- U241e Automatic Transmission

- Automatic Transmission Repair Manual Pdf

- Toyota U140e Transmission Technical Manual

- U241e Transmission Repair

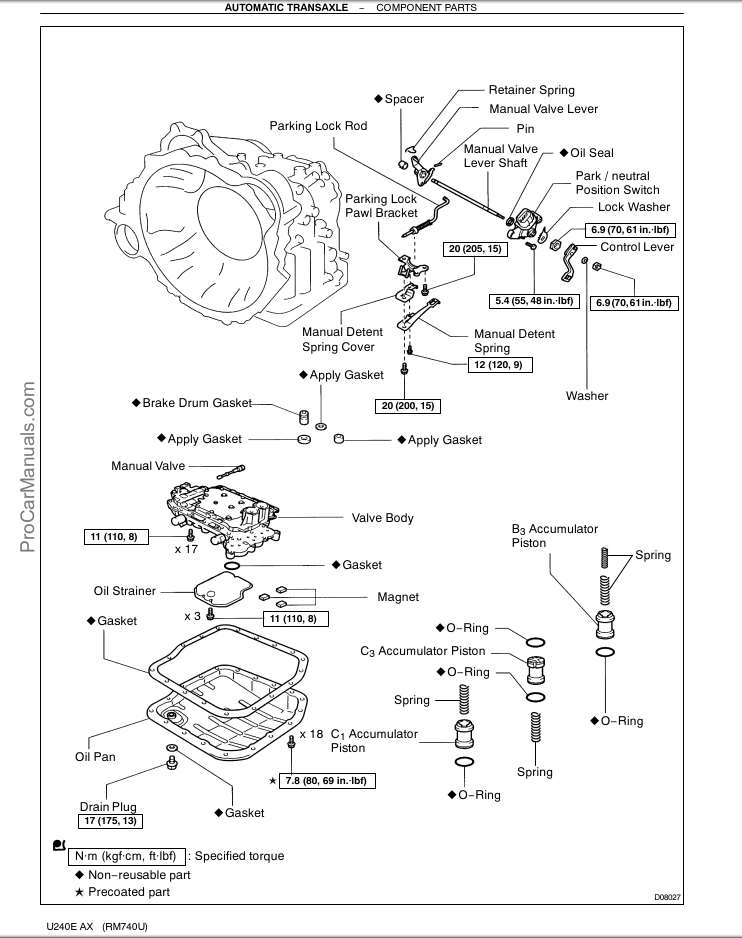

2006 Toyota Avalon Service Repair Workshop Manual DOWNLOAD Original Factory 2006 Toyota Avalon Service Repair Manual is a Complete Informational Book. This Service Manual has easy-to-read text sections with top quality diagrams and instructions. Trust 2006 Toyota Avalon Service Repair Manual will give you everything you need to do the job. 2001-2006 Toyota U241E Automatic Transmission Repair Shop Manual Original. Click on thumbnail to zoom. This factory information shows you how to rebuild your vehicle's automatic transmission. This overhaul manual contains instructions on how to completely disassemble, refurbish, and reassemble the transmission. After it is removed from the. AX–2 U241E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM AX 6. After cleaning, the parts should be arranged in the correct order for efficient inspection, repair, and reassembly. When disassembling a valve body, be sure to match. Toyota Highlander Service Manual: Speed sensor (U241E/U140F) Toyota Highlander Service Manual / Automatic transmission / trans / Speed sensor (U241E/U140F) REPLACEMENT. REMOVE BATTERY. REMOVE AIR CLEANER ASSY. REMOVE AIR CLEANER HOSE NO.1. More about Toyota Highlander: On-vehicle inspection 1. INSPECT FRONT AXLE HUB BEARING. Toyota Highlander Service Manual: Transmission wire (U241E/U140F) Toyota Highlander Service Manual / Automatic transmission / trans / Transmission wire (U241E/U140F) REPLACEMENT. REMOVE ENGINE UNDER COVER NO.1. DRAIN AUTOMATIC TRANSAXLE FLUID. More about Toyota Highlander: Valve clearance (3MZ-FE). TOYOTA/LEXUS U140E/F, U240E – ATSG (Automatic Transmission Service Group) PDF free online. Starting at the beginning of production for the 1998 model year for Lexus and 2000 for Toyota, a new transaxle, designated as the, U140/U240 series was introduced into service.

TOYOTA/LEXUS U140E/F, U240E – ATSG (Automatic Transmission Service Group) PDF free online

Starting at the beginning of production for the 1998 model year for Lexus and 2000 for Toyota, a new transaxle, designated as the, U140/U240 series was introduced into service. This Transaxle’s shift points, and shift feel are electronically controlled by a Powertrain Control Module. This is accomplished by the PCM monitoring engine load and adjusting solenoid duty cycle to match pressure rise and shift feel. The PCM also monitors the turbine and output speed sensors to calculate gear ratio and the Transmission Range Sensor for gear selection. This front wheel drive transaxle has four forward gears, and one reverse gear. The unit is comprised of three connecting clutches, three holding brakes, three planetary gear sets, and two one-way clutches. In addition, there is a clutch located in the torque converter which is applied via the ECM for increased fuel economy. The primary difference between the U140E/F and the U240E is clutch capacity. The U140 series being used primarily in the V6 applications, thus, containing a greater number of friction elements in the individual clutch packs, while the U240 series is utilized primarily in the smaller 4 cylinder engines.

Applications:

U241e Automatic Transmission

U140E

- 2002–2004 Camry (V6)

- 2001–2003 Highlander (V6)

- 1999-2003 Lexus ES 300

- 1999-2003 Lexus RX 300 (FWD)

U140F

- 2001–2003 Highlander (4×4)

- 2001–2010 RAV4 (4×4)

- 1999–2003 Lexus RX 300 (AWD)

- 2009– Matrix (2.4 L) (AWD)

U240E

- 2000–2005 Celica GT-S

- 2003 Matrix XRS (with VVTL-i engine)

- 2000–2006 runx/allex (with VVTL-i engine)

- 2000-2001 Avensis VVTI

Automatic Transmission Repair Manual Pdf

CONTENTS

Toyota U140e Transmission Technical Manual

- TRANSMISSION APPLICATION BY VEHICLE

- IDENTIFICATION CODE STAMPING LOCATION

- COMPONENT APPLICATION CHART

- CONNECTOR AND INTERNAL HARNESS SCHEMATIC

- WIRING DIAGRAM AND CONNECTORS

- TRANSMISSION RANGE SENSOR

- TURBINE AND OUTPUT SPEED SENSORS

- VEHICLE SPEED SENSOR

- DTC DESCRIPTIONS

- TRANSAXLE DISASSEMBLY

- COMPONENT REBUILD SECTION:

- TORQUE CONVERTER HOUSING

- UNDERDRIVE PLANETARY ASSEMBLY

- DIFFERENTIAL ASSEMBLY

- OIL PUMP ASSEMBLY

- DIRECT (C2) CLUTCH

- FORWARD (C1) CLUTCH

- UNDERDRIVE (C3) CLUTCH

- 2ND BRAKE (B1)

- NO. 1 ONE WAY CLUTCH (F1) FREEWHEEL OPERATION

- NO. 2 ONE WAY CLUTCH (F2) FREEWHEEL OPERATION

- VALVEBODY ASSEMBLY

- UPPER VALVEBODY CHECK BALL LOCATIONS

- LOWER VALVEBODY CHECK BALL LOCATIONS

- SOLENOID OPERATION AND CHECK PROCEDURE

- VALVEBODY RE-ASSEMBLY PROCEDURE

- TRANSMISSION FINAL ASSEMBLY

- TORQUE SPECIFICATIONS

- CASE PASSAGE IDENTIFICATION FOR AIR TESTING

- LINE PRESSURE TESTING, TAP LOCATIONS, FLUID CHECKING PROCEDURE

- ECM MEMORY RESET PROCEDURE

- SPECIAL SERVICE TOOLS (SST)

U241e Transmission Repair

Language: English

Format: PDF

Pages: 120